- 18803303309

- karryyan@hbtbls.com

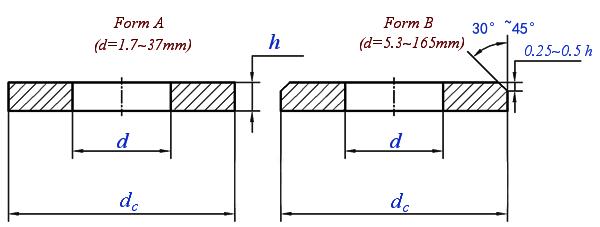

| Item | Flat washer; Plain washer |

| Main products | DIN125 DIN9021 |

| Size | M4-M64 |

| Key words | Flat round washer |

| Material | Carbon steel: Q195, Q235, 1035, 1045, 65Mn |

| Grade | 4.8,8.8,10.9,12.9 |

| Standard | GB, DIN, ISO, ANSI/ASTM, BS, BSW, JIS etc |

| Non-standards | OEM is available, according to drawing or samples |

| Finish | Plain, Zinc Plated(Clear/Blue/Yellow/Black), black , HDG, Dacromet |

| Certification | ISO9001,SGS |

| Package | 5kg 10kg 25kg bag/ carton+pallet or customized. |

| Application | Heavy Industry, Retail Industry, General Industry, Automotive |

|

Size |

M |

d |

dc |

h |

|||

|

For thread size |

min |

max |

min |

max |

min |

max |

|

|

φ3.2 |

M3 |

3.2 |

3.38 |

6.64 |

7 |

0.45 |

0.55 |

|

φ3.7 |

M3.5 |

3.7 |

3.88 |

7.64 |

8 |

0.45 |

0.55 |

|

φ4.2 |

M4 |

4.3 |

4.48 |

8.64 |

9 |

0.7 |

0.9 |

|

φ5.3 |

M5 |

5.3 |

5.48 |

9.64 |

10 |

0.9 |

1.1 |

|

φ6.4 |

M6 |

6.4 |

6.62 |

11.57 |

12 |

1.4 |

1.8 |

|

φ7.4 |

M7 |

7.4 |

7.64 |

13.57 |

14 |

1.4 |

1.8 |

|

φ8.4 |

M8 |

8.4 |

8.64 |

15.57 |

16 |

1.4 |

1.8 |

|

φ10.5 |

M10 |

10.5 |

10.77 |

19.48 |

20 |

1.8 |

2.2 |

|

φ13 |

M12 |

13 |

13.27 |

23.48 |

24 |

2.3 |

2.7 |

|

φ15 |

M14 |

15 |

15.27 |

27.48 |

28 |

2.3 |

2.7 |

|

φ17 |

M16 |

17 |

17.27 |

29.48 |

30 |

2.7 |

3.3 |

|

φ19 |

M18 |

19 |

19.33 |

33.38 |

34 |

2.7 |

3.3 |

|

φ21 |

M20 |

21 |

21.33 |

36.38 |

37 |

2.7 |

3.3 |

|

φ23 |

M22 |

23 |

23.33 |

38.38 |

39 |

2.7 |

3.3 |

|

φ25 |

M24 |

25 |

25.33 |

43.38 |

44 |

3.7 |

4.3 |

|

φ27 |

M26 |

27 |

27.33 |

49.38 |

50 |

3.7 |

4.3 |

|

φ28 |

M27 |

28 |

28.33 |

49.38 |

50 |

3.7 |

4.3 |

|

φ29 |

M28 |

29 |

29.33 |

49.38 |

50 |

3.7 |

4.3 |

|

φ31 |

M30 |

31 |

31.39 |

55.26 |

56 |

3.7 |

4.3 |

|

φ33 |

M32 |

33 |

33.62 |

58.8 |

60 |

4.4 |

5.6 |

|

φ34 |

M33 |

34 |

34.62 |

58.8 |

60 |

4.4 |

5.6 |

|

φ36 |

M35 |

36 |

36.62 |

64.8 |

66 |

4.4 |

5.6 |

|

φ37 |

M36 |

37 |

37.62 |

64.8 |

66 |

4.4 |

5.6 |

|

φ39 |

M38 |

39 |

39.62 |

70.8 |

72 |

5.4 |

6.6 |

|

φ40 |

M39 |

40 |

40.62 |

70.8 |

72 |

5.4 |

6.6 |

|

φ41 |

M40 |

41 |

41.62 |

70.8 |

72 |

5.4 |

6.6 |

|

φ43 |

M41 |

43 |

43.62 |

76.8 |

78 |

6 |

8 |

|

φ46 |

M45 |

46 |

46.62 |

83.6 |

85 |

6 |

8 |

|

φ50 |

M48 |

50 |

50.62 |

90.6 |

92 |

7 |

9 |

|

φ52 |

M50 |

52 |

52.74 |

90.6 |

92 |

7 |

9 |

|

φ54 |

M52 |

54 |

54.74 |

96.6 |

98 |

7 |

9 |

|

φ57 |

M55 |

57 |

57.74 |

103.6 |

105 |

8 |

10 |

|

φ58 |

M56 |

58 |

58.74 |

103.6 |

105 |

8 |

10 |

|

φ60 |

M58 |

60 |

60.74 |

108.6 |

110 |

8 |

10 |

|

φ62 |

M60 |

62 |

62.74 |

108.6 |

110 |

8 |

10 |

|

φ66 |

M64 |

66 |

66.74 |

113.6 |

115 |

8 |

10 |

|

φ70 |

M68 |

70 |

70.74 |

118.6 |

120 |

9 |

11 |

|

φ74 |

M72 |

74 |

74.74 |

123.4 |

125 |

9 |

11 |

(1)What are flat washers for?

Flat washers prevent sinking of bearing surfaces,The main role of flat washers is to increase the size of a screw’s bearing surface area, and reduce the surface pressure applied on the fastened object.

(2)What is the difference between a flat washer and a fender washer?

A fender washer, though similar in shape to a standard washer, differs in that the outside diameter is traditionally much larger in proportion to the center hole. With this design, a fender washer can be placed under the head of a bolt or nut to help distribute forces applied when tightening.

(3)Do I need a flat washer with a lock washer?

Flat washers are used to increase the surface area in order to more evenly distribute the force applied with tightening the fastener. Lock washers are used as a means of creating tension during tightening in order to help keep the nut from working loose later.

(4)What goes first lock washer or flat washer?

When used correctly, a lock washer will hold the nut or other threaded fastener in place. To help it accomplish this, put the lock washer on first, below the fastener. If your project calls for other washers or hardware elements, they should go on before the lock washer so that it can hold them in place.